Easy, consistent access to water is something we often take for granted. However, it’s important to remember that water is a precious and finite resource. For this reason, water management plays a critical role in sustainability efforts and resource conservation.

As industries and communities strive to reduce their environmental footprint and limit depletion of natural resources, wastewater treatment has emerged as a vital solution for safe and effective water recycling. In this blog, we’ll explore wastewater treatment systems, with a particular focus on mobile treatment systems.

Wastewater treatment is a multistage process that transforms contaminated water into a valuable resource that is suitable for various nonpotable applications. Whether at construction sites, remote locations, or disaster relief efforts, mobile water treatment systems provide sustainable access to safe, usable water. By understanding the steps involved, we can appreciate the critical role this process plays in water conservation, environmental stewardship, and the circular economy.

The Essential Steps of Water Treatment

Large-scale treatment facilities and mobile wastewater treatment plants share many of the same steps. Depending on many factors – such as the volume of water to be treated and level of contamination – the complexity of the process and the order of the steps can vary. The following steps provide a general overview.

Step 1: Collection

The first step involves collecting wastewater. Wastewater sources can include industrial processes, municipal sewage systems, construction sites, and plumbing drainage from temporary jobsite housing. This water often contains a range of contaminants, including suspended solids, organic matter, and potential pathogens.

Step 2: Preliminary Treatment

The goal of preliminary treatment is to remove large debris and grit from the wastewater, using screening and sedimentation processes.

Step 3: Primary Treatment

Primary treatment uses physical and chemical processes to remove suspended solids and organic matter.

Step 4: Secondary Treatment

Secondary treatment uses biological processes to remove dissolved organic matter. Common methods include activated sludge systems, trickling filters, and oxidation ponds.

Step 5: Quality Monitoring

Throughout the process, key parameters of the treated water are continuously monitored. This ensures the water is safe for nonpotable uses and suitable for environmental reintegration.

Step 6: Effluent Use

The treated effluent water is piped to a holding tank for on-site use. While nonpotable, this water is suitable for various uses, such as downhole drilling, hydraulic fracturing, dust control, crop irrigation, and wellsite restoration.

Nuances of Wastewater Treatment

As we mentioned earlier, the basic steps are consistent. However, wastewater treatment is a complex process that requires careful consideration of several factors.

- Complexity: The composition of wastewater can vary significantly depending on its source, which requires tailored treatment approaches. Industrial wastewater, for instance, may contain unique contaminants that require specialized treatment methods.

- Standards: To help ensure public health and environmental protection, regulatory agencies establish stringent standards for treated wastewater quality. These standards govern parameters such as pH, dissolved solids, and the acceptable levels of specific contaminants.

- Reuse Potential: Treated wastewater can be repurposed for various nonpotable applications that require varying levels of purity, so water that is suitable for one purpose may require additional treatment for different intended use.

Mobile Wastewater Treatment Solutions

Mobile wastewater treatment systems are designed specifically for on-site water recycling. These trailer-mounted systems provide a convenient and efficient way to manage wastewater.

Many industries and applications rely heavily on mobile wastewater treatment systems. Primarily, this is because their operations are located in remote areas or temporary sites. Here are some examples:

- Oil and gas industry

- Mining industry

- Construction and engineering projects

- Military and disaster relief operations

- Agricultural operations

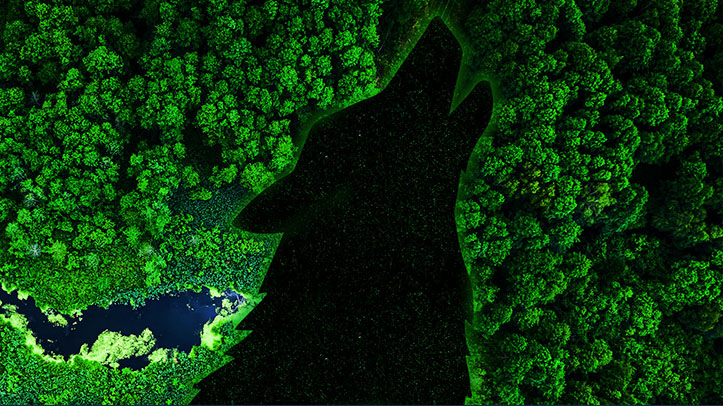

Mobile Wastewater Treatment Systems From WolfPack Industries

WolfPack mobile wastewater treatment systems are equipped with state-of-the-art technologies that are tested and proven to effectively remove contaminants. Designed and manufactured in-house at WolfPack’s Texas manufacturing facility, these mobile systems provide a sustainable, cost-effective way to recycle and repurpose water on location.

Even in the most remote areas, these fully automated recycling systems deliver many advantages:

- Rapid deployment and setup at remote locations

- Flexibility to accommodate varying flow rates and water quality

- Reduced environmental impact by minimizing water transportation

- Cost savings through water reuse and reduced disposal fees

- Compliance with environmental regulations and conservation initiatives

Ready to maximize your nonpotable water potential?

Wastewater treatment plays a crucial role in water conservation and environmental stewardship by transforming contaminated water into a valuable resource. By understanding the treatment process and its nuances, we can appreciate the importance of responsible water management and the potential for water reuse.

WolfPack Industries is at the forefront of mobile wastewater treatment, offering innovative systems that provide safe, efficient water recycling on location. These trailer-mounted units give you a convenient wastewater-management solution that promotes safety, reduces environmental impact and supports sustainability.

Whether you’re outfitting a jobsite or planning ahead for potential disaster response, WolfPack is ready to provide the equipment and expertise you’re looking for. Contact us today, or give us a call at 346-707-8226.